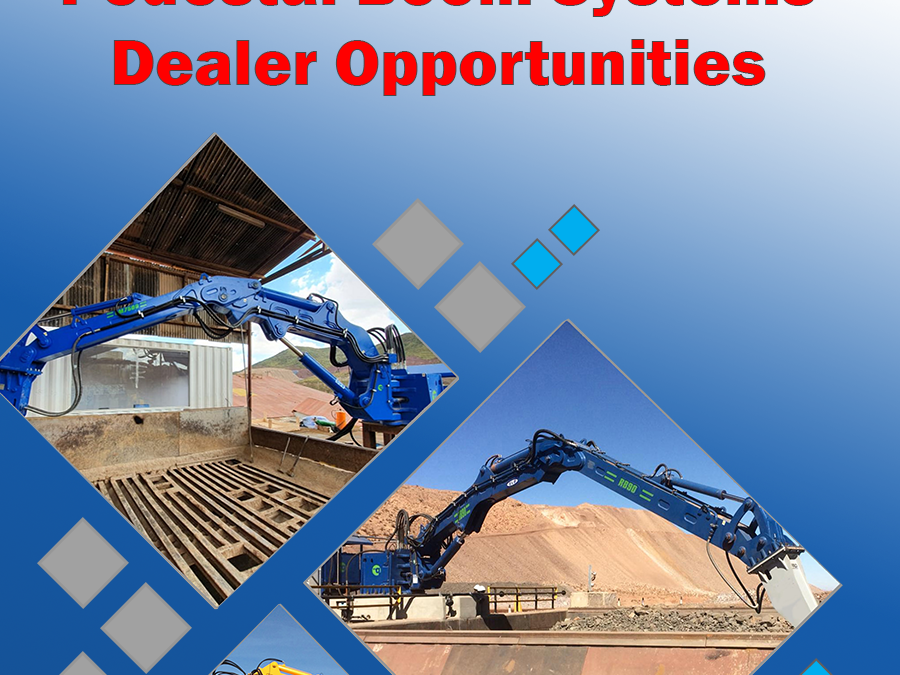

McQuaid Engineering is actively seeking partners to sell and service our pedestal boom systems throughout the US.

We want to partner with businesses that have sound sales experience in selling capital plant within the mining and quarrying sectors to further establish and grow our business in US.

It is our commitment to quality, safety standards and customer satisfaction that has positioned us a world leader in rock breaker boom design.

We want to talk with distributors who share the same values, with the goal of building lasting, mutually beneficial partnerships.

If this sounds like YOUR business, please get in touch with us today!

Email: mq.contact@mcquaidengineering.com for more information or with details about your business.

Recent Comments